Call us now:

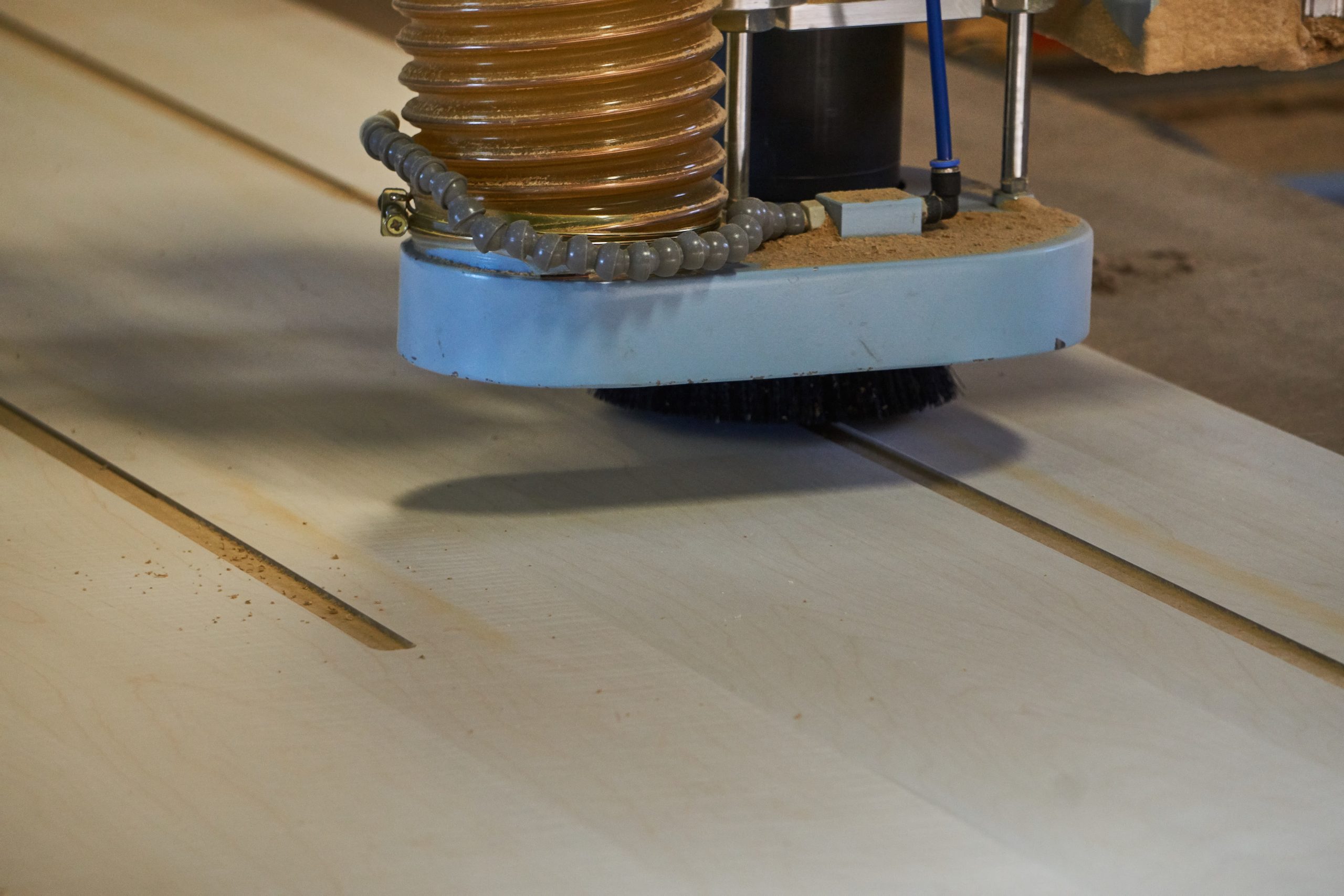

At Wengerd Wood, one of our specialties is cutting CNC cabinet parts.

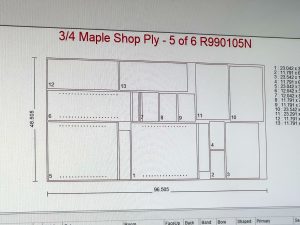

We have both the software and machine capabilities to nest and cut hundreds and even thousands of sheets of plywood parts.

Our cutting services allow you to reduce labor costs, increase finished cabinet quality, increase assembly accuracy, and speed up production timeline all of which will help increase customer satisfaction and profitability.

Various workflows can be developed to fit your needs. We can take your drawings from Cabinet Vision software or other common CAD formats then import, nest, and cut the parts. We also have the capabilities to do engineering in-house, taking the cabinet all the way from a sketch to cut parts based on your requirements.

Features such as a variety of joints, pilot holes, and part labels make cabinet assembly a breeze and ensure a tight and accurate fit and finish.

Mortise, tenon, and blind dado joints.

Make assembly a breeze, no tape measure required!

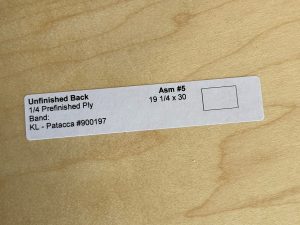

Removable part labels for each part.

Make identification and sorting parts fast and easy! Labels contain information for cabinet number, part name, edgebanding information, and more!

Line boring, hinge boring, drawer guide prep, and pilot holes.

Save tons of assembly time!

State of the art optimizing software.

Gets you the best yield, and saves material!

Frequently Asked Questions

- Our shop has deeply integrated Cabinet Vision software into our workflow, so using Cabinet Vision is the simplest and most reliable way to get accurate parts. If you prefer to do engineering, you can simply send us a PNC file which we can import and optimize while retaining all of your programming.

- We also work with most other common CAD file formats including:

- DXF

- DWG

- AI

- EPS

- We can also work off of hand sketches or PDF drawings to create the parts in our system.

We cut all common cabinet-building materials including:

- Hardwood

- Plywood

- MDF (Medium Density Fiberboard)

- Masonite

- Particle Board

- Laminates

- Plastic / Poly

Contact us if you have questions about our material cutting capabilities.

We are typically able to process most orders in 5-8 business days after we have material and approved drawings.

That said, because we are a job shop and have a number of machines, we can be flexible and will work with you to accommodate your deadlines.

You have a variety of options for picking up your completed product:

- You can pick up your completed product at our shop with the transportation of your choice.

- We can arrange shipping via UPS, LTL common carrier, or other shipping methods.

We do not currently offer edgebanding in-house, but we do have local contacts that offer edgebanding services.