Call us now:

What are the benefits of using a CNC router to cut your components? In this post we will explore various ways CNC router technology can benefit your manufacturing process.

What are the Benefits of using a CNC Router?

Increased efficiency and productivity

CNC routers can dramatically increase efficiency and productivity because a high-quality machine is able to run cycle after cycle of parts without slowing down of loosing accuracy, something that humans cannot do. Therefore, if you are making lots of components with hand work and manual labor, it may be worthwhile exploring whether CNC routing can increase your productivity and precision.

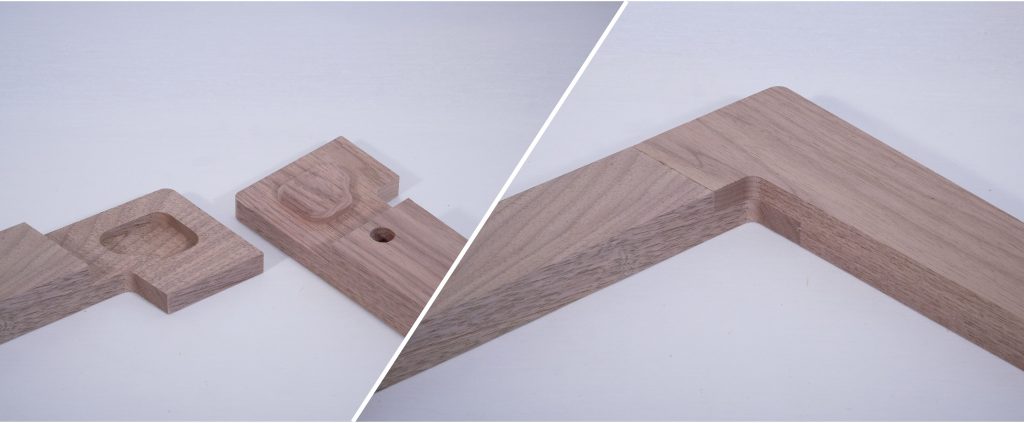

Improved accuracy and precision

While accuracy, precision, and repeatability vary by the build quality and tolerances of CNC machine manufacturer, CNC machines are generally far more accurate and precise than work that is done manually. When working with wood, it is typically possible to hold tolerances of 0.01″ or less, and depending on material, even greater accuracy is possible. If you need to make parts that need to fit together or fit into other components then CNC routers will provide the most consistent means for ensuring that the components remain in tolerance.

Consistency and repeatability

Making several parts with manual machinery may be a very doable task, however, when you need to cut tens, hundreds, or thousands of parts, maintaining accuracy and consistency with manual machinery may be difficult. CNC routers eliminate this problem because they are able to follow exactly the same cutting path time and time and time again, ensuring that every part remains in tolerance. Additionally, it doesn’t matter if the next job is the next day or if it is several years in the future, the CNC routers will be able to cut exactly the same parts that were cut the first time.

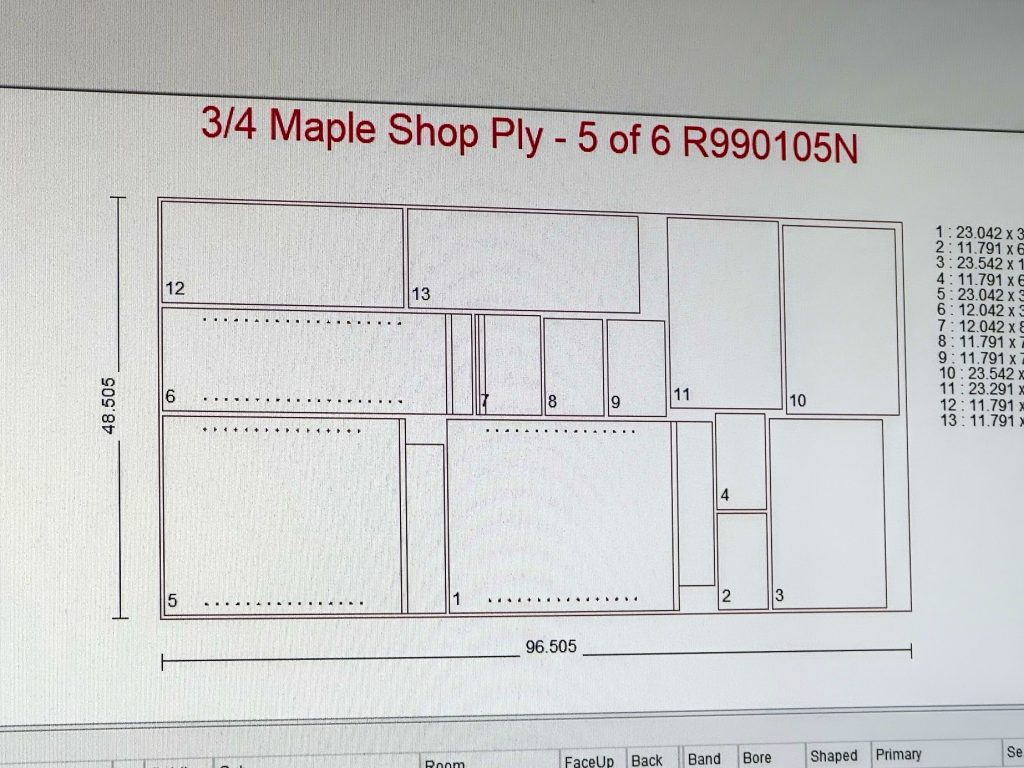

Reduced waste and material usage

Another benefit of CNC routers is that they can reduce waste and material usage. One of the most obvious applications for this is in the cabinet industry, where many parts are nested onto plywood sheets. For instance, by using nesting software, you can optimize many parts onto sheets, saving both material and labor time.

Reduced labor costs and increased safety

CNC routers can also reduce labor costs and increase safety. Because of the efficiency and consistency of the components, assembly is much easier. Additionally, features like mortises, tenons, and dados can make assembly tape measure free, allowing for both faster and more accurate assembly. Safety is also increased because features can be milled without the use of equipment like chop saws, table saws, and shapers, which can put body parts in close contact with cutting tools.

Potential for increased profits and business growth

Using CNC routers can also increase profits and help your business grow. By freeing up labor hours, increasing quality and accuracy, and reducing scrap, you can add dollars to your bottom line. Additionally, you can increase your throughput, allowing greater capacity for increasing top line sales.

Industries that benefit from CNC routers

There are many industries that benefit from CNC routing technology. Some of them include:

- Woodworking and Cabinetry

- Sign-making and advertising

- Furniture manufacturing

- Prototyping and product development

- Aerospace and automotive

In each of these industries, the production capacity and accuracy of the machines allows for increased production, safety, and accuracy.

Conclusion

There are many benefits to using CNC routers:

- Efficiency

- Throughput

- Accuracy

- Precision

- Consistency

- Repeatability

- Reduce Waster

- Reduce Labor Cost

- Increased Profit

Because of all these benefits, many modern manufacturers will benefit from CNC router technology. It may be well worth your time to explore whether CNC routing can benefit your manufacturing process.

Interested in CNC routing services? Contact us for a free quote.